Refrigerated Freight Challenges: Best Practices for Maintaining Product Integrity

September 3, 2024

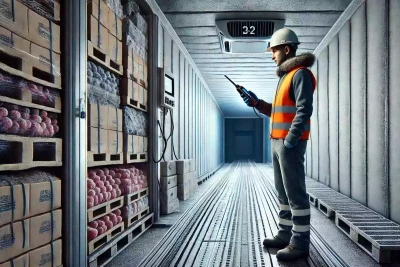

Transporting temperature-sensitive goods presents a unique set of challenges, especially when it comes to maintaining the integrity of the product from the point of origin to its final destination. The complex logistics involved in ensuring that refrigerated freight arrives at the right temperature require both careful planning and attention to detail. Here, we explore some of the critical factors and best practices for successfully managing refrigerated shipments.

Transporting temperature-sensitive goods presents a unique set of challenges, especially when it comes to maintaining the integrity of the product from the point of origin to its final destination. The complex logistics involved in ensuring that refrigerated freight arrives at the right temperature require both careful planning and attention to detail. Here, we explore some of the critical factors and best practices for successfully managing refrigerated shipments.

One of the most significant challenges in refrigerated freight is ensuring that the product remains at the correct temperature throughout the journey. A common issue arises when products are not adequately pre-chilled before loading. For instance, if goods are not kept in cold storage long enough to lower their core temperature, even the best refrigeration units might struggle to maintain the necessary conditions. This can lead to the reefer unit operating continuously at high speed, ultimately causing the load to be refused upon arrival due to temperature discrepancies.

Loading practices also play a critical role in maintaining temperature. Ensuring that products are loaded correctly—with adequate space around all sides for air circulation—can prevent hot spots and uneven cooling. Even when products are loaded properly, other factors, such as the distance between the product and the trailer doors, can influence the overall temperature consistency.

When a refrigerated trailer backs into a dock, one key decision is whether to shut off the reefer unit. On one hand, leaving the unit on can pull warm air into the trailer, especially if the dock itself is not temperature controlled. On the other hand, shutting off the unit can result in a loss of temperature monitoring, which is crucial for ensuring that the product remains within the desired range.

“If you’re going into a refrigerated dock, you should shut the unit off when backing into the door, so you don’t pull in warm air,” says Triple T Transport Senior Sales Executive John Mahle. “But if you shut the unit off, you also lose your ability to record temperature.”

What are the best practices for loading and unloading refrigerated freight to maintain product integrity? Gain valuable insights from leaders in the field of cold transport in the latest episode of the Stay In Your Lane Podcast.

This decision becomes even more complex when dealing with multi-stop deliveries, where the reefer unit’s performance needs to be carefully managed to ensure that the last delivery is just as cool as the first.

“When it comes to shutting the unit off, if it’s a one-pick, one-drop, I wouldn’t disagree with that,” says Nathan Helms, Director of Transportation Management at Organic Valley, a producer of sustainably made dairy products. “But our business is often multiple stops. So, if you’re at the first receiver in Florida and you open that back door with the unit shut off, you’re turning that trailer into an Easy Bake Oven for the other stops.”

Modern refrigeration units come equipped with telematics that provide detailed data on the temperature inside the trailer throughout the journey. These systems can offer real-time insights, showing exactly how the reefer unit is performing and whether the temperature has been maintained within the desired range. However, it’s important to remember that while telematics can indicate the air temperature, they may not always reflect the core temperature of the product itself. This is why communication between stakeholders remains important.

Modern refrigeration units come equipped with telematics that provide detailed data on the temperature inside the trailer throughout the journey. These systems can offer real-time insights, showing exactly how the reefer unit is performing and whether the temperature has been maintained within the desired range. However, it’s important to remember that while telematics can indicate the air temperature, they may not always reflect the core temperature of the product itself. This is why communication between stakeholders remains important.

“As a responsible shipper, you need to know the receiver’s process so you can have an intelligent conversation about the way issues happen,” says Joe Lombardo, Founder and President of Ege Avenue Associates. “I think you have to bring in carriers to better educate shippers and receivers, because a lot of people still don’t get it.”

For instance, if a product was loaded warm, the reefer unit might still maintain a consistent air temperature, but the product could remain too warm internally. This discrepancy highlights the importance of using both telematics data and physical temperature checks, such as pulping the product upon arrival, to ensure accuracy.

At Triple T Transport, our decades of experience providing 3PL services for refrigerated and frozen freight help us navigate the complexities of temperature-sensitive shipments. We understand the critical importance of maintaining product integrity from the point of origin to the final destination, and our commitment to excellence ensures that our customers’ products arrive in optimal condition. By leveraging advanced technology, rigorous protocols, and a deep understanding of the cold chain, we provide reliable 3PL services that protect your valuable goods and uphold your reputation.